The Essential Guide to Cold Drawn Seamless Tubing in Construction

Cold drawn seamless tubing is a critical component in various construction and decorative applications, offering superior strength and adaptability. Unlike welded tubes, seamless tubing is manufactured without joints, which enhances its durability and reduces the likelihood of structural failures. This makes it an ideal choice for environments that require enhanced mechanical properties and resist

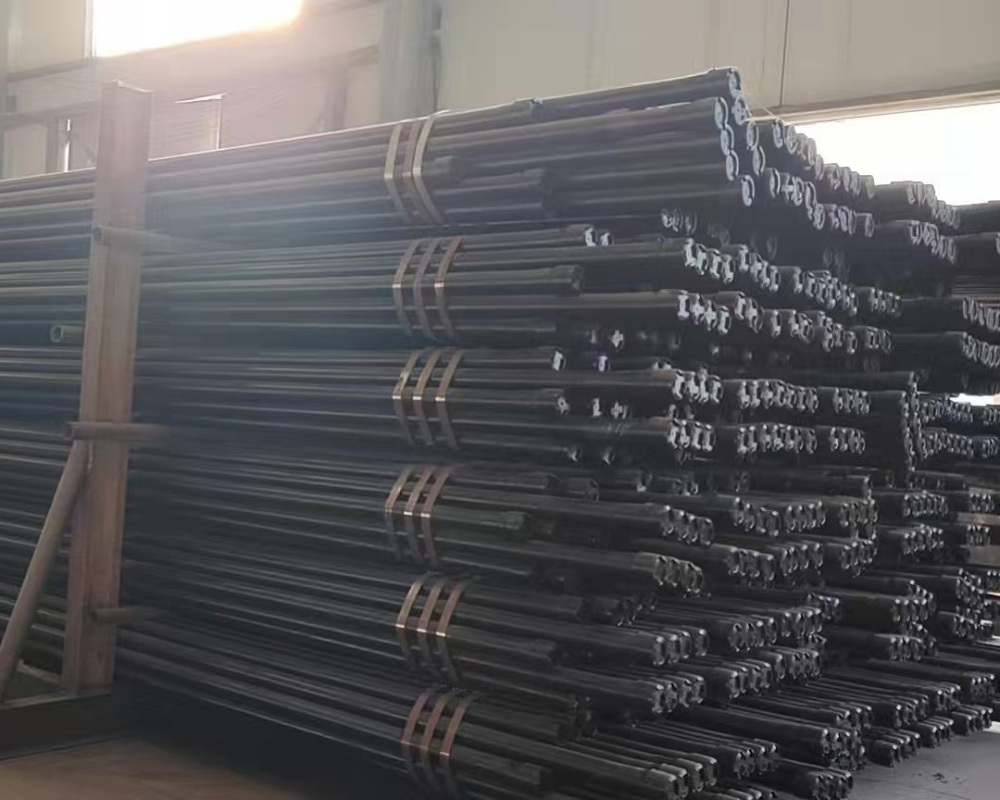

Cold drawn seamless tubing is a critical component in various construction and decorative applications, offering superior strength and adaptability. Unlike welded tubes, seamless tubing is manufactured without joints, which enhances its durability and reduces the likelihood of structural failures. This makes it an ideal choice for environments that require enhanced mechanical properties and resistance to pressure.

The manufacturing process of cold drawn seamless tubing begins with solid round steel bars that are heated and pierced to create a hollow tube. This initial stage is followed by a series of cold drawing processes, where the tubing is pulled through a die, reducing its diameter and increasing its length while simultaneously enhancing its tensile strength. This cold working process not only improves the physical properties of the metal but also enhances its surface finish, making it more suitable for architectural applications.

One of the primary advantages of cold drawn seamless tubing is its ability to withstand high pressure and temperatures, which is essential in construction applications where safety and reliability are paramount. Additionally, the seamless design minimizes the risk of leaks and failures in high-stress environments, making it a preferred choice for structural support and fluid transportation systems.

Cold drawn seamless tubing is widely used in industries including construction, automotive, and manufacturing. In the construction sector, it plays a pivotal role in scaffolding, handrails, and other structural elements, ensuring that buildings and infrastructures are both safe and aesthetically pleasing. Its smooth finish and resistance to corrosion further enhance its appeal in decorative applications, allowing for a combination of functionality and style.

When selecting cold drawn seamless tubing for a specific project, it is important to consider factors such as material grade, diameter, and wall thickness. These specifications can greatly impact the tubing's performance and suitability for different applications. Collaborating with knowledgeable suppliers can provide insights into the best options tailored to your project’s unique requirements.

In conclusion, cold drawn seamless tubing is an indispensable material in the building and decoration industry, offering a blend of strength, durability, and aesthetic appeal. Understanding its properties and applications can help stakeholders make informed choices that contribute to the overall success of construction projects. Whether you are involved in structural engineering or interior design, incorporating cold drawn seamless tubing can enhance both the functionality and visual impact of your designs.

The manufacturing process of cold drawn seamless tubing begins with solid round steel bars that are heated and pierced to create a hollow tube. This initial stage is followed by a series of cold drawing processes, where the tubing is pulled through a die, reducing its diameter and increasing its length while simultaneously enhancing its tensile strength. This cold working process not only improves the physical properties of the metal but also enhances its surface finish, making it more suitable for architectural applications.

One of the primary advantages of cold drawn seamless tubing is its ability to withstand high pressure and temperatures, which is essential in construction applications where safety and reliability are paramount. Additionally, the seamless design minimizes the risk of leaks and failures in high-stress environments, making it a preferred choice for structural support and fluid transportation systems.

Cold drawn seamless tubing is widely used in industries including construction, automotive, and manufacturing. In the construction sector, it plays a pivotal role in scaffolding, handrails, and other structural elements, ensuring that buildings and infrastructures are both safe and aesthetically pleasing. Its smooth finish and resistance to corrosion further enhance its appeal in decorative applications, allowing for a combination of functionality and style.

When selecting cold drawn seamless tubing for a specific project, it is important to consider factors such as material grade, diameter, and wall thickness. These specifications can greatly impact the tubing's performance and suitability for different applications. Collaborating with knowledgeable suppliers can provide insights into the best options tailored to your project’s unique requirements.

In conclusion, cold drawn seamless tubing is an indispensable material in the building and decoration industry, offering a blend of strength, durability, and aesthetic appeal. Understanding its properties and applications can help stakeholders make informed choices that contribute to the overall success of construction projects. Whether you are involved in structural engineering or interior design, incorporating cold drawn seamless tubing can enhance both the functionality and visual impact of your designs.

TAG:

Related Posts

The Essential Guide to Cold Drawn Seamless Tubing in Construction

Cold drawn seamless tubing is a critical component in various construction and decorative applications, offering superior strength and adaptability. Unlike welded tubes, seamless tubing is manufactured without joints, which enhances its durability and reduces the likelihood of structural failures. This makes it an ideal choice for environments that require enhanced mechanical properties and resist